Laboratory

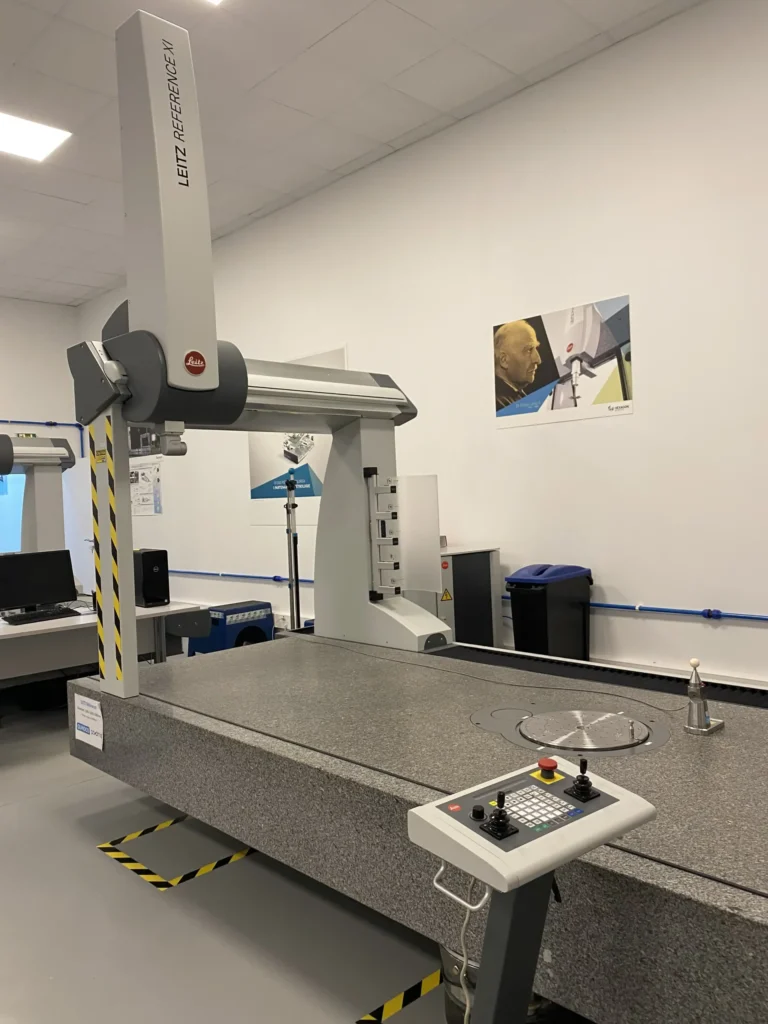

Metrology

An expert in CMM inspection, Sematec Métrologie is currently the French dimensional metrology market leader.

THE KEY TO OUR GROUP’S SUCCESS STEMS FROM 4 FACTORS:

– The technical expertise of our 80 Coffmet-certified metrologists

– The variety of our machine fleet (40 conventional and optical coordinate-measuring machines, 9 measurement arms with laser scanner, 3 laser trackers, 3 CT scanners, 1 AICON BOX robotic cell, roughness meters, profile meters, endoscopes, etc.)

– The responsiveness of our sales and technical teams

– Proximity with 6 offices throughout France

For the last 15 years, Sematec Métrologie has registered an annual growth rate of 10%, thanks to our teams, customers, and partners.

On-site

Metrologist

On-site assignment of CMM metrologist

In France and internationally, from a few days to several months…

Do you have your own CMM equipment, and are you experiencing a peak in activity?

We can provide you with metrologists to use your equipment:

• CMM (Coordinate-measuring machines): on Pcdmis (DEA – Hexagon Metrology), Metrolog X4 and XG, Mcosmos (Mitutoyo), Calypso (Zeiss), Quindos (Leitz – Hexagon Metrology) software

• OCMM (optical CMMs): Optiv, OGP, Microvu, Microna, Mitutoyo

• Measurement arms: Hexagon romer on Polyworks,

Power Inspect, Metrolog X4 software, etc.

• Laser tracker: Leica on Polyworks software.

Schedules tailored to your pace: daytime, teamwork,

shift work, public holidays, summertime, etc.

We have the expertise tailored to your needs:

Level 1

Running workpieces on CMMs

and conventional inspections

Level 2

Creation of on-site or

offline mode inspection procedures

Level 3

Training your teams on CMM metrology

and on reading plans

Offline

Program

Our technicians are capable of offline programming on all of the following software programs: QUINDOS, COSMOS, PCDMIS, Metrolog X4, Calypso, etc.

For example, offline programming can be performed:

• For a new project: After conducting a plan review with the customer, we can create inspection procedures.

• When investing in new software: We can convert inspection procedures from the old software to the new software.

In any case, a plan review is scheduled with the customer to work out their expectations and understand their work methods.

This will enable our technicians to propose the most suitable solutions for their needs.

For the first programs developed, our technicians can install them directly on site to validate their conformity.

Afterwards, we can provide you with remote support for future programs.

Specific

measurements

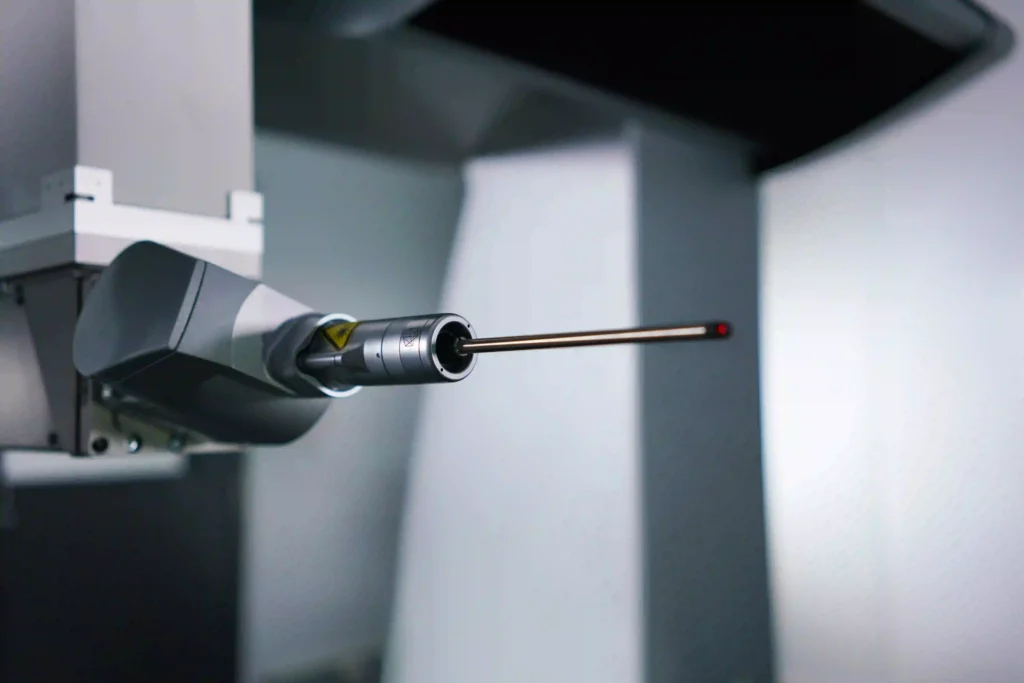

1 – Optical CMM inspection

To measure small-size workpieces, we use OCMMs (optical coordinate-measuring machines) equipped with an ultra-high performance automatic video measuring system.

This measurement is performed using a camera and different illumination levels.

The dimension acquisition process is high-speed and precise (precision from 2 µm), and is comparable to automated profile projection inspection.

These machines are generally coupled with a probe for some Z-axis measurements.

This type of device equipped with monochromatic light enables high-quality investigation thanks to its powerful zoom (e.g. watch gears, or ultra-thin part measurements).

With different possible illumination types (profile, coaxial, diascopic or fragmented), we can thus measure workpieces made of different materials to account for light reflection.

Our laboratories are equipped with virtually all optical CMM brands:

OGP, Mitutoyo, Microvu, Optiv and Microna.

We provide an array of services:

• workpiece measurement on our machines

• programming on multi-cavity fixtures for in-factory measurement (QVPACK, Pcdmis, Measuremind, InSpect Vision and Measure X software).

The maximum size of our measurement tables is 450 mm x 450 mm.

2 – Blade CMM inspection

One of Sematec’s areas of business is blade coordinate-measuring machine inspection.

We use tailored software allowing us to create a visual adaptation of our customers’ requirements.

This sector requires good programming skills and a higher level of expertise than in other conventional metrology sectors.

Quindos software continues to be the gold standard for blade metrology.

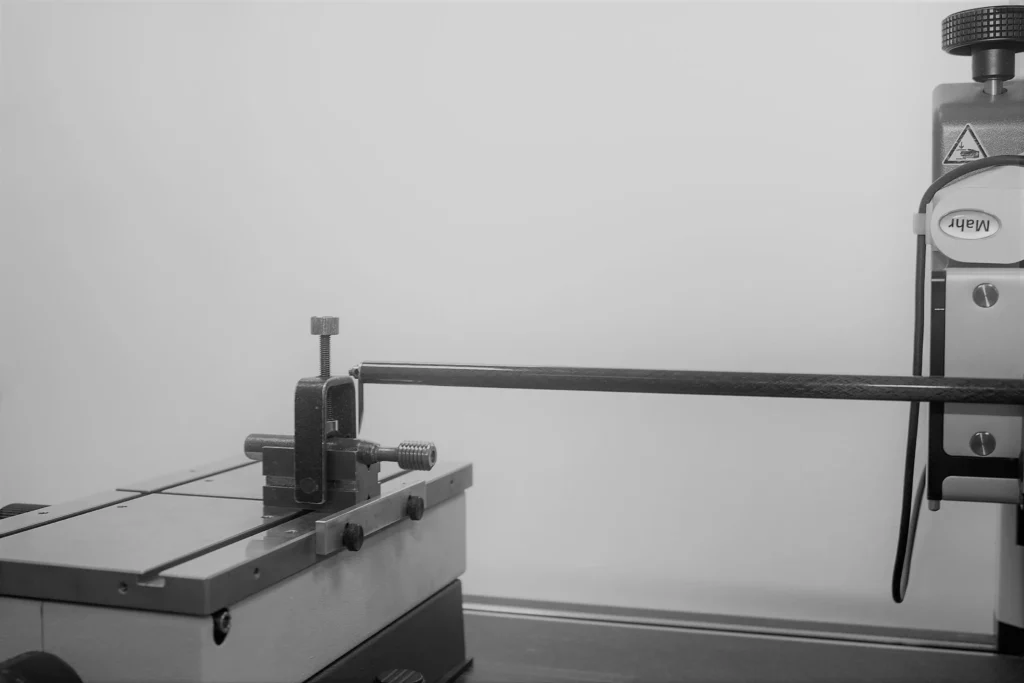

3 – Profile meter / roughness meter CMM inspection

PROFILE MEASUREMENT

For workpiece profile condition metrology, the Sematec Métrologie group has invested in a number of profile meters and contour scopes.

Profile meters are high-precision measuring devices:

+/- 1.25 µm per 25 mm measured and +/- 1.75 µm per 75 mm measured (subject to change depending on the machines).

We make these measurements on all workpiece types:

from metal workpieces for the aviation sector to plastic workpieces for the automotive or luxury sectors.

Our high-tech procedures enable us to access the most specific surfaces and thereby optimise measurement.

Results are sent to you in PDF or Excel format, and include profile characteristic graphs and curves.

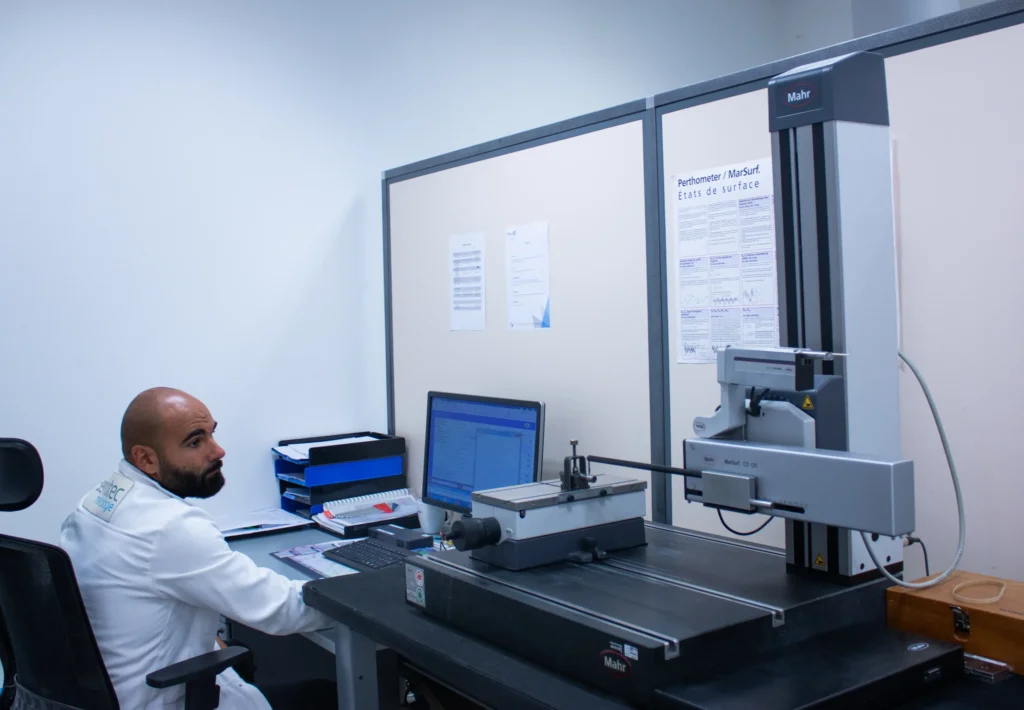

ROUGHNESS MEASUREMENT

For workpiece surface condition metrology, the Sematec Métrologie group has invested in a number of roughness measuring devices.

These devices allow us to measure surface conditions on all workpiece types: plastic or metal workpieces, for all industrial sectors: automotive, aviation, medical, packaging, etc.

Using multiple styli, we can inspect:

• arithmetic roughness Ra

• maximum roughness Rz

• profile height Pt

• average depth R

• maximum groove depth Rmax

• average pitch R

Results can be given in values or in graphic format.

We use the following brands:

• Mitutoyo

• Mahr