Our other services

Calibration

of your measuring instruments

At our LA FRETTE site, we calibrate the following instruments:

– Gauge: smooth and threaded plug, smooth and threaded ring

– Standard: standard measuring rod, standard smooth ring

– Variable dimension: slide gauge, external and internal micrometre, depth gauge and comparator

– Torque: screwdriver and torque wrench

– On-site service: measurement column and profile projector

– Contracted service (COFRAC option): gauge block, temperature, force, pressure, etc.

About calibration:

Calibration consists of comparing the values indicated by the instrument with the standard’s true values.

Calibration is essential for monitoring your instrument fleet and meeting your needs.

Following this calibration, a conformity or non-conformity assessment is delivered according to the standard in question.

Turnaround: 1 week from receipt (depending on quantity)

All our standards are COFRAC-accredited

Additional services:

– Instrument dispatch and delivery shuttle service

– Instrument fleet management

– OPTIMU software supply

We can supply you with measuring instruments from TESA, a Swiss company which is one of the leading names in dimensional metrology, and which has been present on the premium market since 1941!

Training

Our highly experienced COFFMET-certified metrologists facilitate training in a range of areas: dimensional metrology software, ISO dimensioning training, marble plate measurement training, profile meter/roughness meter training, etc.

Training is provided on our premises or on-site on your company premises.

Training courses are tailored to specific requests around your plans and your workpieces. They help your teams update, consolidate or upgrade their expertise.

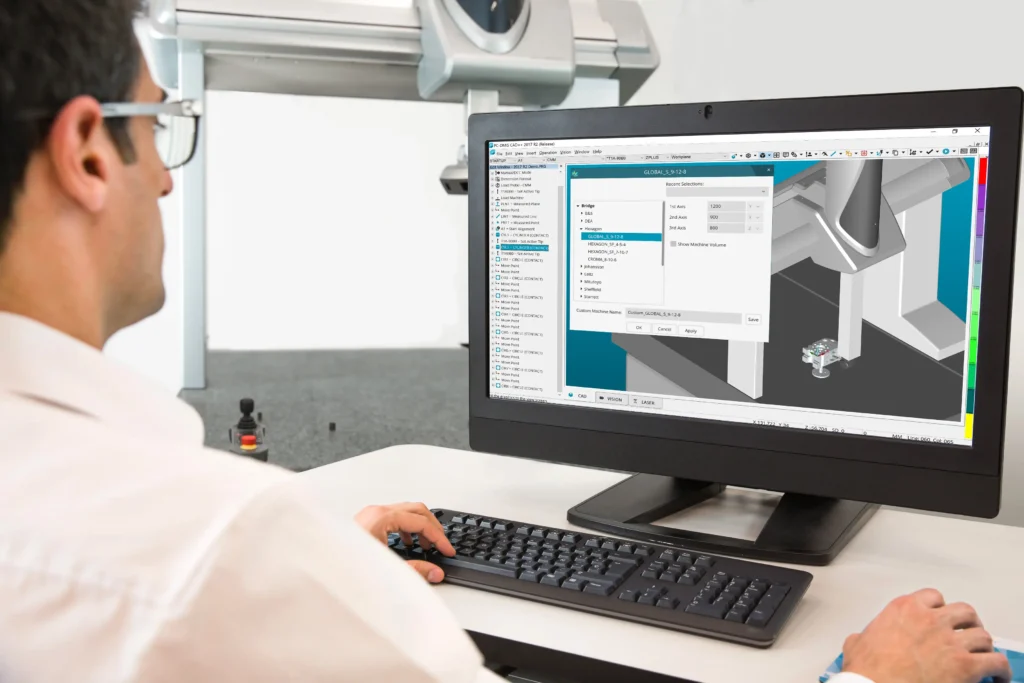

Our Software

Please contact us for other software solutions

QUALIOPI via our HMI group

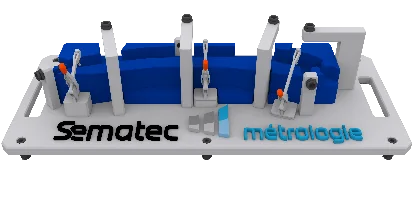

Turnkey projects

Do you need to set up a metrology department? Replace a machine, integrate a new measurement procedure? SEMATEC METROLOGIE is the perfect partner to help you build up your department.

Project review:

Plans, inspection methods, etc.

Inspection fixture

Offline programming

On-site installation

Training

Tailored coaching

➟ Inspection methods according to process

➟ Measurement organisation

➟ Production run inspection optimisation

➟ CMM cycle time reduction